Nylon is a plastic that is molded into amenities. It is a useful synthetic material in many industries. Nylon ropes are made of nylon drawn in to fibers.Read More…

Since our beginning in 1967, we have had experience designing, manufacturing and distributing the highest quality braided ropes and cords. Braided ropes and cordage are produced in all common fibers.

Atkins & Pearce is a leading manufacturer of braided technical textiles based in Covington, Kentucky. We produce and process industrial cordage and twine, coated insulation sleeving, tubing, expandable sleeving, lacing tapes, tie cords, candlewick, and custom braided textile products. All of our products are produced with quality top-of-mind and state-of-the-art equipment to ensure the best...

At Franklin Braid, we are passionate about the art and science of ropes. With years of expertise and a deep commitment to quality, we have earned our reputation as a premier provider of an extensive range of ropes. Let us introduce you to our world of ropes and our unwavering dedication to our craft. Ropes are our specialty, and our product range reflects our commitment to delivering a diverse...

We are a manufacturer of high quality rope that is used in a variety of applications including arbor, climbing, guiding, industrial safety, rope rescue, work access and OEM. We are committed to innovative processes and product development. Call or visit us online today for me detailed information. We look forward to working with you soon!

Sunshine Cordage manufactures and distributes synthetic rope. Our product consists of stranded rope available in 3, 8, & 12; solid braided and double braided rope, mooring lines, specialty rope and twines available in polypropylene and polyester. We offer ropes in many materials such as nylon, polyethylene, and manila. Sunshine’s ropes serve many applications and industries including...

Whether you need rope for heavy pulling or everyday decoration, Hercules Bulk Ropes can help. Since 1975, Hercules Bulk Ropes supplies the highest quality rope at competitive prices. We want to be your number one source for all your rope needs. Our prices will entice you, but our customer-friendly service and expertise will keep you coming back again and again!

More Nylon Rope Suppliers

Nylon Making Process

Nylon creates the strongest synthetic rope, resistant to stretching and stress. Nylon ropes are resistant to water, shock absorption, and abrasion. Nylon ropes will stay strong through rot, mold, mildew, oil, gasoline, chemicals, UV rays, and wind.

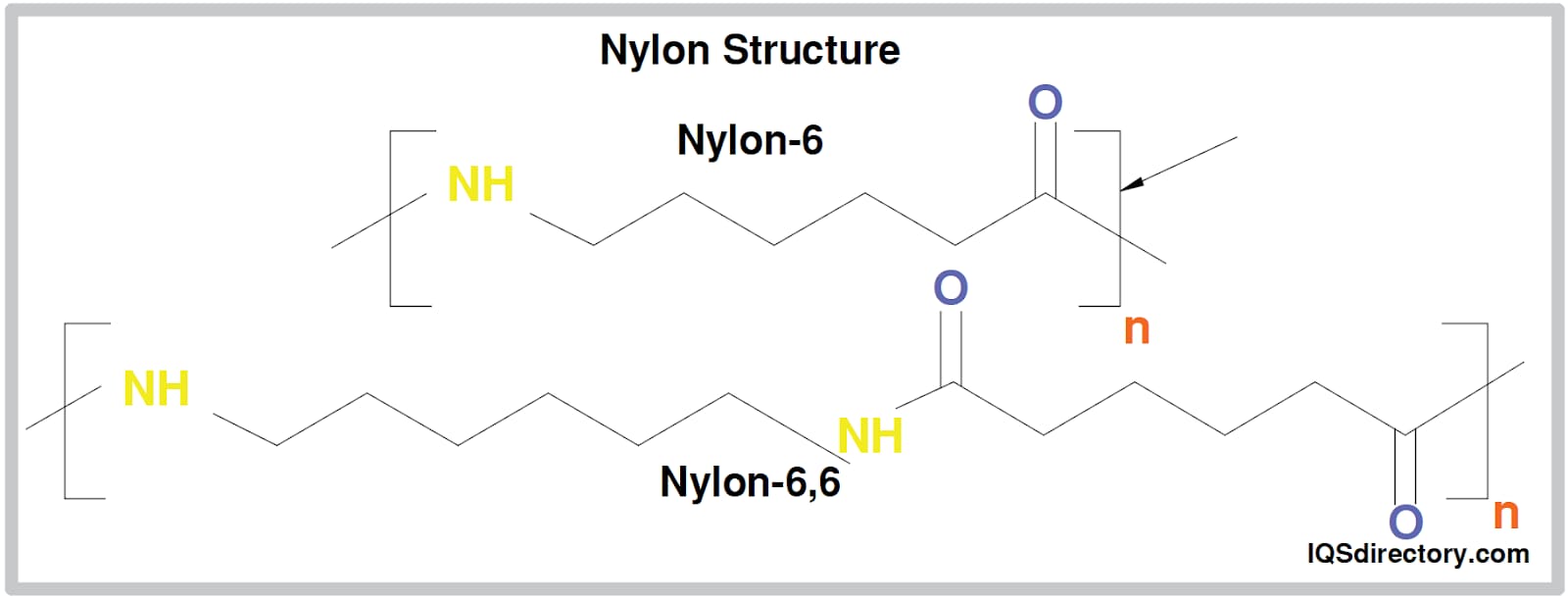

“Nylon” refers to polymers that are linear polyamides. There are two ways to make Nylon used in fiber applications. In the first method, molecules with amino (NH2) groups interact with those with acidic (COOH) groups. The result is ‘Nylon 66’. The number 66 means that there is 6 carbon on each monomer.

The salt known as nylon, created when two chemicals are combined, has a precise acid-to-base ratio of 1:1. To eliminate the water and create the polymer, the salt is heated after being dried.

The alternative method involves polymerizing a chemical with an amine at one end and an acid at the other to create a chain with repeating units of (-NH-[CH2] n-CO-) x. If n = 5, another frequent version of this polymer, nylon, is referred to as nylon 6. Caprolactam, which uses an open-ring polymerization, is the first step in manufacturing nylon 6 for commercial use.

Both methods include melting polyamide, drawing it after cooling and obtaining the desired characteristics for each intended usage.

Properties of Nylon

- Lustrous

- Elastic

- Damage resistant to several chemicals and oil

- Resilient

- Does not absorb water

- Dries quickly

Advantages of Using Nylon Ropes

Disadvantages of Nylon Ropes

Nylon rope absorbs water and weakens when wet or submerged in water is one of its few disadvantages. Although operationally insignificant, nylon rope is frequently used for mooring and anchor lines. Here is a list of a few drawbacks of nylon ropes:

- In water, nylon ropes become dissociated.

- Polyamides, which make up nylon rope, fall short of the substance's requirements for aquatic environmental stability.

- In both freshwater and saltwater, nylon ropes deteriorate. The former affects Nylon material to wear down more quickly than the latter.

Conclusion

It is obvious that using nylon rope has many benefits, and as a result, it can be utilized for various applications.

Choosing the Proper Nylon Rope Manufacturer

To make sure you have the most productive outcome when purchasing nylon rope from a nylon rope manufacturer, it is important to compare at least 5 manufacturers using our nylon rope directory. Each nylon rope manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each nylon rope business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple nylon rope businesses with the same quote.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services