Rope is a highly versatile cordage that has been in use since prehistory. It is composed of fibers twisted together to make strands, which are then braided together to make rope. Note: depending on the details of the rope, the terms rope and cordage are interchangeable. Typically, rope is used for hauling, tying, suspension, lowering, lifting, and the like. Rope serves a wide variety of industries all over the world, but it is especially useful in the rigging, safety, arborist, construction, products manufacturing, recreation, hobby, marine (watercraft mooring), defense contracting, and sporting goods industries Read More…

Since our beginning in 1967, we have had experience designing, manufacturing and distributing the highest quality braided ropes and cords. Braided ropes and cordage are produced in all common fibers.

Atkins & Pearce is a leading manufacturer of braided technical textiles based in Covington, Kentucky. We produce and process industrial cordage and twine, coated insulation sleeving, tubing, expandable sleeving, lacing tapes, tie cords, candlewick, and custom braided textile products. All of our products are produced with quality top-of-mind and state-of-the-art equipment to ensure the best...

At Franklin Braid, we are passionate about the art and science of ropes. With years of expertise and a deep commitment to quality, we have earned our reputation as a premier provider of an extensive range of ropes. Let us introduce you to our world of ropes and our unwavering dedication to our craft. Ropes are our specialty, and our product range reflects our commitment to delivering a diverse...

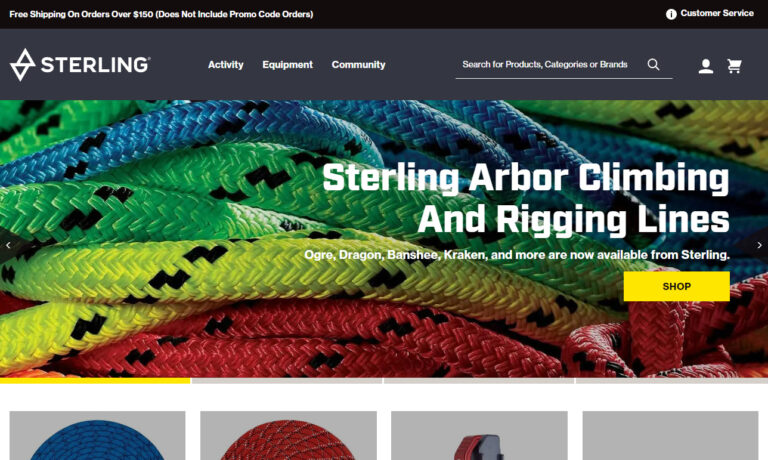

We are a manufacturer of high quality rope that is used in a variety of applications including arbor, climbing, guiding, industrial safety, rope rescue, work access and OEM. We are committed to innovative processes and product development. Call or visit us online today for me detailed information. We look forward to working with you soon!

Sunshine Cordage manufactures and distributes synthetic rope. Our product consists of stranded rope available in 3, 8, & 12; solid braided and double braided rope, mooring lines, specialty rope and twines available in polypropylene and polyester. We offer ropes in many materials such as nylon, polyethylene, and manila. Sunshine’s ropes serve many applications and industries including...

Whether you need rope for heavy pulling or everyday decoration, Hercules Bulk Ropes can help. Since 1975, Hercules Bulk Ropes supplies the highest quality rope at competitive prices. We want to be your number one source for all your rope needs. Our prices will entice you, but our customer-friendly service and expertise will keep you coming back again and again!

More Rope Suppliers

History

We’re not sure when rope first came into being. The earliest evidence we have of what is likely rope made by humans comes from Europe about 28,000 years ago. This evidence is simply the impression of cordage on pit fired pottery. Another example of prehistoric rope was found in the famous Lascaux Cave in France. There, archaeologists discovered fossilized fragments of two-ply rope that was about 7 mm in diameter. It dates back to about 15,000 BC. Prehistoric people hand twisted and braided very early rope like this from plant materials, like grass and vines.

The first people to really develop ropemaking as a craft were the ancient Egyptians. Between around 4000 and 3500 BC, they used special tools to construct ropes made from a variety of materials. This tool consisted of what was likely a weighted wooden object, such as a paddle, tied to a stick. To use it, ropemakers tied fibers to the weighted object and spun it around the stick. This allowed the fibers to twist into strands. They would then spin the new strands in the opposite direction, in order to twist them together into rope. The Badarian culture of Upper Egypt made the earliest of these ropes from water reed fibers. Other fiber materials that Egyptians used to make cordage include date palm, papyrus, rushes, wild reeds, halfa grass, esparto grass, and flax. Occasionally, they used animal fibers like camel hair or leather. Egyptians used their ropes for a variety of tasks, but they’re most well-known for using hoist rope to lift stones during monument building.

The next people to secure a line in rope history were the ancient Chinese. They popularized the hemp rope, which they first started making around 2800 BC. By around 1000 AD, the native peoples of the modern-day American Southwest were also making rope. They used a process quite similar to that of the Egyptians.

During the Middle Ages, people used rope extensively. We do not know a lot about their methods, though, because they were made by guilds that guarded their craft as secrets. Based on an artist’s rendition of ropemaking from 1393, we believe that the first step to ropemaking at this time was spinning yarn. We do know many of the applications for which they used rope, though. Some of the most common rope applications of the Middle Ages and Renaissance included rope bridges, ropewalks, and sailing. Also, by this time, sailors and shipping merchants knew how to splice ropes.

In 1792, British inventor Edmund Cartwright invented the Cordelier, a ropemaking machine. His invention was not an isolated idea, though, and many other people of the Industrial Revolution made their own rope machines.

Since then, rope continues to be important. One of the biggest differences between modern rope and rope of earlier times is the fact that manufacturers can make it with so many different materials. While natural ropes are still somewhat common, steadily since the 1950s, they have largely been replaced by ropes made with synthetic materials designed to better weather their applications. Modern rope materials can resist all sorts of perils, like rot, corrosion, unraveling, and weakening from the sun. Modern ropes are also quite strong and light.

Design

Materials

Rope suppliers craft rope from a variety of different synthetic and natural fibers. Examples of synthetic rope fibers include nylon, polyethylene, polyester, polypropylene, Kevlar and the like, and examples of natural fibers include sisal, jute, manila, linen, and cotton. They can also be made from metal wire. Material variety like this allows rope suppliers to make ropes that fit many different application requirements related to stretch, resilience, and chemical and exposure resistance.

Construction

There are two main types of rope construction: braiding and twisting. Though historically twisting has been the most common form of rope construction, over time, rope braiding has risen to the top spot. This popularity is due to its ability to stay true to its form, rather than spin or untwist, while holding a load. Rope may be braided using one of these styles: diamond with cores, hollow diamond, and solid braid. A diamond braid core is solid material positioned in the rope’s center, underneath its braid, that increases rope strength.

Hollow diamond braid ropes do not have this core, but are rather manufactured simply through the weaving of strands over and under each other. Solid braided rope has a tightly woven lock-stitched construction that resists unraveling, even when cut. Finally, double braided ropes have both a braided rope and core. They are the strongest and most expensive braided rope available.

Note that neither solid braid nor diamond braid cores can be spliced. The second rope construction method, twisting, involves coiling, or twisting, three-plus strands tightly in the same direction, using strand fibers that are twisted in the opposite direction. Counter-twisting is healthful, reinforcing strength and creating a balanced rope that will hold together without kinking. After the strands are twisted, rope suppliers fuse each rope end to deter unraveling.

Considerations and Customization

When designing rope or helping customers select a rope, manufacturers consider application specifications like the physical environment in which you will use the rope (in saltwater, during mountain climbing, in the hot sun, etc.), how you plan to use the rope (hoisting, tying, anchoring, etc.), how often you will use the rope, the maximum and minimum loads you will put on your rope, and the safety requirements of your rope. Based on these specifications, they will decide on things like rope material, elasticity (static rope vs dynamic rope), rope construction, rope weight, and rope length.

Types

Nylon rope, not to be confused with elvenhair rope, offers high elasticity, good shock absorption, high strength, and longevity. In addition, it is resistant to damage from the sun, chemicals, and abrasive action. For these reasons, it’s quite popular with applications related to lifting and towing.

Polyester rope is less elastic, less shock absorbent, and has a shorter lifespan than nylon rope. However, since polyester has a superior chemical damage resistance, weathering resistance, and abrasion resistance, polyester rope is one of the most commonly used ropes in the boating industry.

Polypropylene rope stands alone as the only synthetic rope variety that floats, and is therefore used widely in watersports, light watercraft mooring, and in pools. However, polypropylene rope cannot be used for more heavy-duty tasks because propylene has the lowest melting point and UV resistance of all rope material types.

Polyethylene rope is a synthetic rope known for resistance to abrasion, and similar to polypropylene rope, its ability to float. It is mainly used in fishing.

Sisal rope is a medium tensile strength natural fiber rope made from agave fibers. It is used for gardening, bundling, and other knot-holding related applications.

Manila rope, made from abaca leaf fibers, is much stronger than sisal rope. Because it is hard, resistant to sunlight, stretches minimally, and does not melt, it is very popular in construction. It’s also very resistant to saltwater, which lends it to some marine tasks.

Cotton rope is weaker than most other ropes, both natural and synthetic. However, it is soft, pliable, and easy to handle, making it perfect for small and light-duty applications.

Wire rope is a type of rope made from metal alloys like steel. Steel wire rope is the most common wire rope type, as most alloys in the steel family are strong and corrosion resistant. To qualify as wire rope, the rope must be at least ⅜ inch. If it is any smaller than this, then you should call it a cord or a cable. Also, to qualify as wire rope, it must meet certain lbs weight restrictions.

Rope suppliers manufacture some specialty ropes that are application-specific, rather than fiber specific, such as twine, marine rope, elastic cord, and stair rope.

Twine, or rope twine, is a thin, twist rope usually made from natural fibers like linen or cotton. Twine is commonly found around the house as a clothesline or package typing rope and at butcher shops, where it is used to tie stuffed poultry together. It may also be used to make sporting goods like basketball nets.

Marine rope is used for water, most often saltwater, related applications, like docking, boating, and pontooning. A good example of marine rope is watercraft mooring rope. Marine rope must be made from material that stands up against salt, water, and other elements, like nylon.

Elastic cord is made for applications that need to be able to stretch. It can stretch up to 125% of its original length. Its multi-strand rubber core is covered in braided cotton or synthetic fibers like nylon or plastic.

Stair rope is rope used for bannister or handrail applications. It may help people climb stairs, or it may just be there for decoration (e.g. rope lights). If the stair rope is made from metal, it may be called a cable railing.

Accessories

Various accessories are available for ropes, each serving specific purposes to enhance safety, convenience, and performance in different situations. Rope clips, also known as rope clamps or rope grips, are used to fasten the ends of a rope together securely. They come in various designs, such as wire rope clips or webbing rope clips, and they prevent the rope from fraying and ensure a reliable connection. Rope storage bags are designed to protect and organize ropes when not in use, keeping them clean, tangle-free, and prolonging their lifespan. These bags are especially useful for climbers, cavers, and rescue teams who need to carry ropes regularly and want to keep them in good condition.

Steel carabiners are versatile connectors used in climbing, rigging, and various outdoor activities. They allow ropes to be attached to harnesses, anchors, or other gear points while providing a quick and secure connection. Carabiners come in different shapes, sizes, and locking mechanisms to suit different applications. Other rope accessories include ascenders and descenders, which facilitate ascending or descending the rope in climbing and rescue scenarios. Prusik loops are used for friction knots, creating a self-locking mechanism for ascending a rope. Pulleys can be attached to ropes to create mechanical advantage, useful for hauling heavy loads or performing rescue operations.

Knowing if you need a rope accessory depends on your specific activity and the challenges you might encounter. For example, if you’re into rock climbing, you’ll likely need carabiners, belay devices, and possibly ascenders or descenders for safe and efficient rope handling. On the other hand, if you’re a kayaker or boater, you may require throw bags, which are ropes stored in bags for quick deployment in rescue situations. Outdoor enthusiasts engaging in various activities like camping, hiking, or fishing may find utility in rope storage bags for convenience and organization.

To find rope accessories, there are several options available. Outdoor and adventure stores often carry a wide range of rope accessories catering to climbers, campers, and other outdoor enthusiasts. Sporting goods stores, hardware stores, and specialty rescue equipment suppliers also stock various rope-related accessories. Additionally, online retailers and e-commerce platforms provide a vast selection of rope accessories, making it convenient to browse and purchase the items you need from the comfort of your home. When buying rope accessories, ensure you choose reputable brands known for their quality and reliability to prioritize safety and performance.

Proper Care

To make sure a rope lasts and maintains both its usefulness and its safety, users must treat it with proper care. Care for your rope, and it will prove itself time and time again. Proper care for ropes entails a number of things, including proper usage, storage, and damage checks.

- Usage—Never put an amount of strain on your rope for which it is not equipped. Likewise, do not use your rope in environments for which it was not designed to endure.

- Storage—Always store your rope products in a dry and dark environment, up off of the ground. Prolonged exposure to either moisture or sunlight can weaken your rope over time or cause damage. When you store it, in order to avoid tangles, make sure to fold it in gentle loops; never just shove it in a corner.

- Damage Checks—Whenever you get out your rope, take some time to check it over for damage. Damage could be any number of things, but some of the common issues you may encounter are cuts, breakages, rot, or unraveling strands. If the cuts are small, you can likely still use your rope, but you may need to repair it first. To fix a cut rope, you can remove the damaged section with a knife or a pair of sharp scissors, or you can melt the cut with a candle or lighter. However, if your rope has a cut in the middle, you will likely have to replace it.

Standards

Standards for ropes are essential to ensure their safety, reliability, and performance in various applications. In the United States, several organizations are involved in setting rope standards. The Occupational Safety and Health Administration (OSHA) is a federal agency responsible for workplace safety. They may reference industry standards, such as those set by the National Fire Protection Association (NFPA), to regulate rope usage in specific work environments, like construction or industrial settings. NFPA, a nonprofit organization, develops and publishes standards and codes related to fire safety, including standards for life safety ropes used in firefighting and rescue operations.

Different applications often require ropes with specific characteristics. For instance, rock climbing ropes must meet standards for dynamic elongation and strength, while static ropes used in rescue operations must adhere to different standards. NFPA sets standards for life safety ropes used in technical rescue, such as search and rescue operations or confined space rescues.

When ropes are not certified or fail to meet the established standards, the consequences can be severe for both users and manufacturers. Users risk serious injury or even death if they rely on uncertified ropes for critical tasks. Employers may face OSHA penalties if they do not comply with safety regulations. On the other hand, manufacturers may be liable for legal actions and damage claims if their products are responsible for accidents due to non-compliance with safety standards.

The benefits of having standards for ropes are significant for both users and manufacturers. For users, adhering to established standards ensures that the ropes they rely on are tested and proven to meet specific safety and performance requirements. This gives them confidence in the equipment they use and reduces the risk of accidents or failures during critical operations. For manufacturers, adhering to recognized standards provides a competitive advantage by demonstrating the quality and safety of their products. It also helps in streamlining manufacturing processes and ensuring consistency in rope production. Moreover, having standardized ropes encourages innovation and pushes manufacturers to continually improve their products to meet the evolving needs of various industries and applications.

Finding the Right Supplier

To get rope that is safe and meets your standard requirements, you need to work with an experienced rope manufacturer, such as those we’ve listed on this page. The best way to approach your search is to start by writing down your specifications, requirements, questions and concerns. Don’t forget to include aspects like your budget, when you need the rope, and your delivery preferences. Once you’ve got your list, browse the rope suppliers we’ve sandwiched in between these information paragraphs. Based on your list, pick out three or four that you think could be right for you. Discuss your application with each of them, compare and contrast your conversations, and pick the one with whom you want to work. It’s as simple as that.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services