A rope comprises several yarns, plies, fibers, or strands braided or twisted together to make a thicker and more durable structure. Ropes are often used for dragging and pulling. Rope is stronger than thread, string, or twine. Read More…

Since our beginning in 1967, we have had experience designing, manufacturing and distributing the highest quality braided ropes and cords. Braided ropes and cordage are produced in all common fibers.

Atkins & Pearce is a leading manufacturer of braided technical textiles based in Covington, Kentucky. We produce and process industrial cordage and twine, coated insulation sleeving, tubing, expandable sleeving, lacing tapes, tie cords, candlewick, and custom braided textile products. All of our products are produced with quality top-of-mind and state-of-the-art equipment to ensure the best...

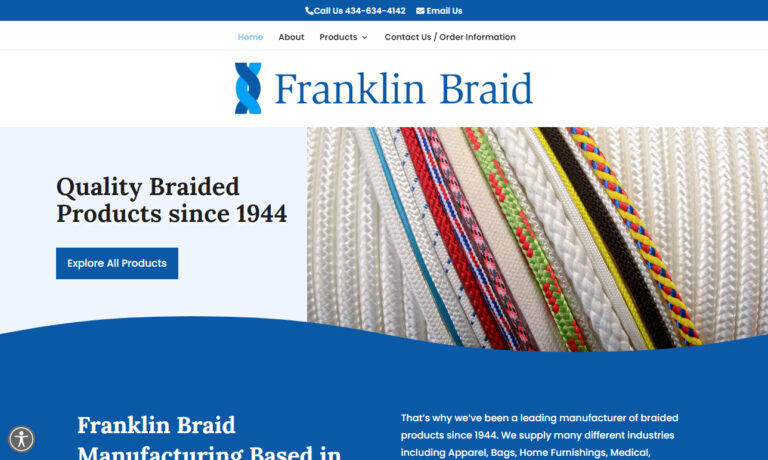

At Franklin Braid, we are passionate about the art and science of ropes. With years of expertise and a deep commitment to quality, we have earned our reputation as a premier provider of an extensive range of ropes. Let us introduce you to our world of ropes and our unwavering dedication to our craft. Ropes are our specialty, and our product range reflects our commitment to delivering a diverse...

We are a manufacturer of high quality rope that is used in a variety of applications including arbor, climbing, guiding, industrial safety, rope rescue, work access and OEM. We are committed to innovative processes and product development. Call or visit us online today for me detailed information. We look forward to working with you soon!

Sunshine Cordage manufactures and distributes synthetic rope. Our product consists of stranded rope available in 3, 8, & 12; solid braided and double braided rope, mooring lines, specialty rope and twines available in polypropylene and polyester. We offer ropes in many materials such as nylon, polyethylene, and manila. Sunshine’s ropes serve many applications and industries including...

Whether you need rope for heavy pulling or everyday decoration, Hercules Bulk Ropes can help. Since 1975, Hercules Bulk Ropes supplies the highest quality rope at competitive prices. We want to be your number one source for all your rope needs. Our prices will entice you, but our customer-friendly service and expertise will keep you coming back again and again!

More Cordage Suppliers

Making Cordage

When making cordage, textile strands are stretched out by hand for hundreds of yards before being hooked at one end to form cordage. Making cordage rope, known as "rope walking," involves turning a wheel that twists the material into a rope. Over the years, innovative machinery has been developed to facilitate the rope walking process. Manufacturers make rope in two ways: twisting and braiding. Although the finished goods have a similar appearance, the procedures differ.

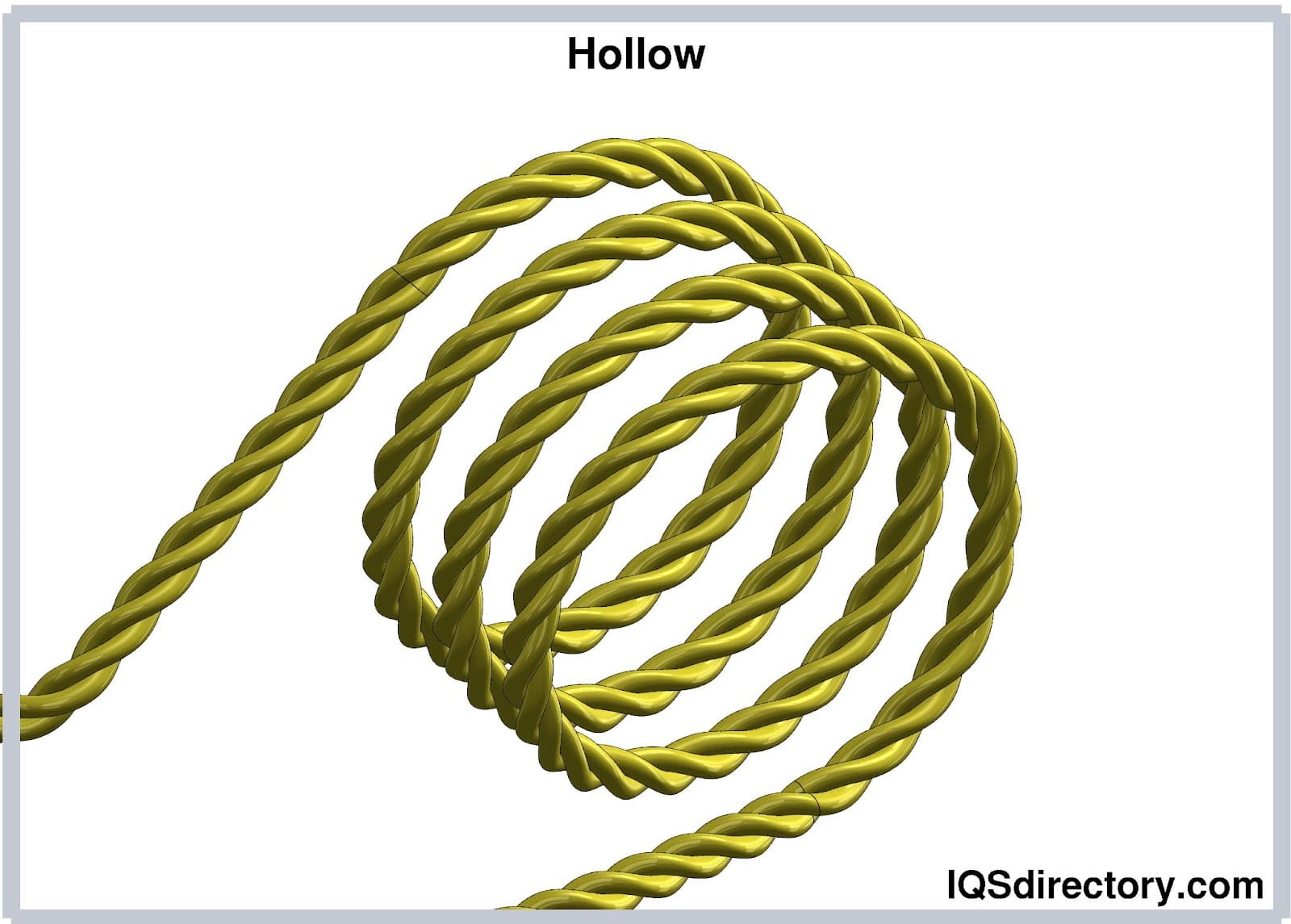

Braided Rope

Braided rope is made by braiding together multiple strands of rope. Hundreds of strands can be incorporated into one braid. There are three variations of braiding: hollow, solid, and double.

Hollow: Hollow braided rope is a braided tube made of fibers with an empty core in the middle.

Solid: Solid braided rope has a core, making it a stronger alternative to hollow rope.

Double: Double braided rope has a braided core and a braided jacket to add even more tensile strength.

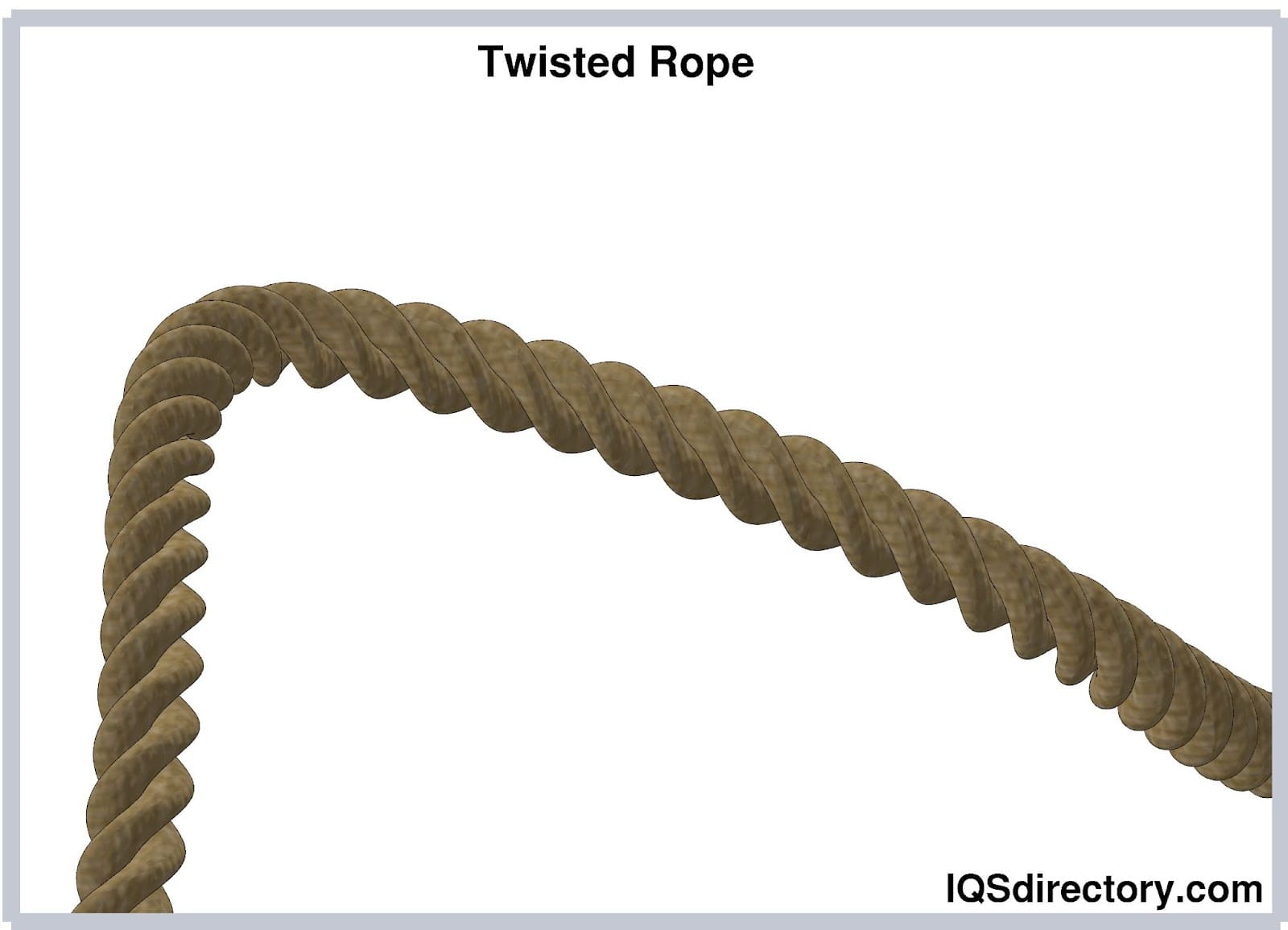

Twisted Rope

Individual strands are first twisted to create a twisted rope, which is then twisted once more to create a larger, stronger rope. Twisted rope's low cost, extensibility, and splice ease are primarily its benefits.

Applications of Cordage

Bridge and Building Inspection: Ropes facilitate manual inspection processes during construction on bridges and tall buildings. Inspectors can walk across high-altitude constructions safely using high-quality ropes.

Construction: Rope has a wide range of applications in the construction sector. It can be more cost-effective to drop technicians into difficult-to-reach areas with secure ropes than to build scaffolding.

Rescue Operations: Since ancient times, the rope has been a necessary component of rescue efforts because it allows workers to reach places that might not otherwise be reachable. The rope has shown to be one of the most dependable equipment in the arsenal of possibilities available to rescue workers since it is very dependable, does not conduct electricity, and is rarely harmed by chemicals or water.

Heavy Lifting: Using rope is an affordable, reliable alternative to wire sling for lifting heavy objects. Rope slings are designed for rigging, cranes, and other lifting equipment. They are incredibly dependable, safe, and lightweight. In addition, the rope can help prevent injury from loads that snap, rebound, or drop due to poor rigging.

Mining: For many years, the underground activities of the mining sector have utilized wire. Unfortunately, wire will rust and create fishhooks and kinks, which leads to dangerous situations. Ropes and cordage are stronger and safer alternatives to wire. Ropes used in mining are more dependable, simpler to see, and engineered to endure longer.

Ocean Work & Boating: The rope used for ocean operations is often pre-stretched to prevent it from elongating while being used. Nautical ropes are also chemically protected against the effects of salt water, and strong enough to endure fish attacks. The presence of salt water, which can cause any material to degrade, is one of the main issues with operating near the ocean. Boating and shipping ropes must be made of unique materials that can endure the harsh temperatures and climate of the ocean. Cordage is also used to fasten hatches, lift sails, and secure cargo.

Military: Rope is often used in military operations to secure equipment and navigate difficult terrain. It has long been a crucial tool used in endurance training.

Choosing the Correct Cordage Supplier

To make sure you have the most productive outcome when purchasing cordage from a cordage supplier, it is important to compare at least 4 companies using our list of cordage suppliers. Each cordage supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each cordage business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple cordage businesses with the same message.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services