Marine rope, also known as nautical rope, is an essential component of many marine activities. It is a versatile and durable material that has been used for centuries in various marine applications. In this article, we will discuss the processes used to create various types of marine rope, different materials used to create marine rope, and challenges, benefits, and various applications of marine rope. Read More…

Since our beginning in 1967, we have had experience designing, manufacturing and distributing the highest quality braided ropes and cords. Braided ropes and cordage are produced in all common fibers.

Atkins & Pearce is a leading manufacturer of braided technical textiles based in Covington, Kentucky. We produce and process industrial cordage and twine, coated insulation sleeving, tubing, expandable sleeving, lacing tapes, tie cords, candlewick, and custom braided textile products. All of our products are produced with quality top-of-mind and state-of-the-art equipment to ensure the best...

At Franklin Braid, we are passionate about the art and science of ropes. With years of expertise and a deep commitment to quality, we have earned our reputation as a premier provider of an extensive range of ropes. Let us introduce you to our world of ropes and our unwavering dedication to our craft. Ropes are our specialty, and our product range reflects our commitment to delivering a diverse...

We are a manufacturer of high quality rope that is used in a variety of applications including arbor, climbing, guiding, industrial safety, rope rescue, work access and OEM. We are committed to innovative processes and product development. Call or visit us online today for me detailed information. We look forward to working with you soon!

Sunshine Cordage manufactures and distributes synthetic rope. Our product consists of stranded rope available in 3, 8, & 12; solid braided and double braided rope, mooring lines, specialty rope and twines available in polypropylene and polyester. We offer ropes in many materials such as nylon, polyethylene, and manila. Sunshine’s ropes serve many applications and industries including...

Whether you need rope for heavy pulling or everyday decoration, Hercules Bulk Ropes can help. Since 1975, Hercules Bulk Ropes supplies the highest quality rope at competitive prices. We want to be your number one source for all your rope needs. Our prices will entice you, but our customer-friendly service and expertise will keep you coming back again and again!

More Marine Rope Suppliers

Variations of Marine Rope

Marine rope can vary in several ways, such as its manufacturing process and its intended use. Here are some common types of marine rope, the different processes used to create them, and their specific application.

Twisted Rope

This type of marine rope is made by twisting two or more strands of fibers together in the same direction. The strands are then twisted together in the opposite direction to form a final product. Twisted rope is usually less expensive than braided rope, but it can unravel and weaken over time.

Braided Rope

Braided rope is made by interlacing several strands of fibers together. The strands are braided in a specific pattern to create a rope that is strong, durable, and less likely to unravel than twisted rope. Due to these properties, braided rope is commonly used for a wide range of marine applications, including mooring lines, tow lines, and sailboat rigging.

Plaited Rope

Plaited rope is similar to braided rope, but the strands are woven together in a specific pattern to create a flatter and smoother rope. This type of rope is often used for decorative purposes or as a decorative cover over a stronger rope.

Kernmantle Rope

Kernmantle rope consists of a braided core (the kern) covered by a braided sheath (the mantle). The core provides strength and durability, while the sheath protects the core from wear and tear. This type of rope is commonly used for climbing, rescue, and other high-stress applications.

Wire Rope

Wire rope is made up of multiple strands of steel wire twisted together to form a rope. Wire rope is incredibly strong and durable, making it ideal for heavy lifting and construction activities.

Types of Marine Rope Materials

There are several types of materials used as marine rope, including natural fiber rope, synthetic fiber rope, and wire rope. Natural fiber rope, such as manila or hemp, is biodegradable and commonly used for mooring and rigging applications. Synthetic fiber rope, such as polyester or nylon, is strong, durable, and resistant to weather conditions, making it ideal for sailing, fishing, and rescue operations. Wire rope is made up of multiple strands of steel wire, providing excellent strength and durability for heavy lifting and construction activities.

Challenges with Marine Rope

Marine rope faces several challenges due to the harsh marine environment. The rope is constantly exposed to saltwater, which can cause corrosion and weaken the material. UV rays can also damage the fibers, reducing the strength and lifespan of the rope. Additionally, wear and tear from friction and use can cause the rope to break or become damaged.

Benefits of Marine Rope

Marine rope has several benefits, including its strength and durability, versatility, cost-effectiveness, and ease of use and maintenance. The strength and durability of marine rope make it suitable for heavy lifting and towing, while its versatility allows it to be used in various marine applications. It is also cost-effective compared to other materials and easy to maintain, making it a popular choice for marine activities.

Applications of Marine Rope:

Marine rope has a wide range of applications in the maritime industry and beyond. Some of the most common applications include:

Mooring

Marine rope is used to secure boats and ships to docks, buoys, and other stationary objects. It provides a strong and reliable connection that can withstand the forces of wind, waves, and currents.

Towing

Marine rope is used to tow boats, barges, and other vessels. It is strong enough to handle the weight and forces involved in towing, and it can be easily attached and detached as needed.

Anchoring

Marine rope is used to anchor boats and ships in place. It is typically attached to an anchor that is dropped to the sea floor, providing a secure hold that can withstand the forces of wind and waves.

Fishing

Marine rope is used in commercial and recreational fishing to catch and hold fish. It can be used as part of nets, traps, and lines to create a wide range of fishing setups.

Safety

Marine rope is used for safety purposes, such as creating lifelines and harnesses for workers on ships and offshore platforms. It can also be used to create safety barriers and fences around hazardous areas.

Decorative

Marine rope is also used for decorative purposes, such as in nautical-themed home decor, boat and yacht interiors, and outdoor landscaping. Its natural fibers and textures can add a touch of rustic charm to any setting.

Choosing the Right Marine Rope Supplier

To ensure you have the most positive outcome when purchasing marine rope from a marine rope supplier, it is important to compare several companies using our directory of marine rope suppliers. Each marine rope supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each marine rope business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple marine rope companies with the same form.

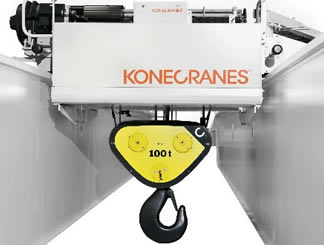

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services