A rope comprises braided or twisted yarns, plies, fibers, or strands. Ropes are used for dragging, lifting, pulling, and securing things. A rope is thicker and stronger than thread, string, and twine. Read More…

Since our beginning in 1967, we have had experience designing, manufacturing and distributing the highest quality braided ropes and cords. Braided ropes and cordage are produced in all common fibers.

Atkins & Pearce is a leading manufacturer of braided technical textiles based in Covington, Kentucky. We produce and process industrial cordage and twine, coated insulation sleeving, tubing, expandable sleeving, lacing tapes, tie cords, candlewick, and custom braided textile products. All of our products are produced with quality top-of-mind and state-of-the-art equipment to ensure the best...

At Franklin Braid, we are passionate about the art and science of ropes. With years of expertise and a deep commitment to quality, we have earned our reputation as a premier provider of an extensive range of ropes. Let us introduce you to our world of ropes and our unwavering dedication to our craft. Ropes are our specialty, and our product range reflects our commitment to delivering a diverse...

We are a manufacturer of high quality rope that is used in a variety of applications including arbor, climbing, guiding, industrial safety, rope rescue, work access and OEM. We are committed to innovative processes and product development. Call or visit us online today for me detailed information. We look forward to working with you soon!

Sunshine Cordage manufactures and distributes synthetic rope. Our product consists of stranded rope available in 3, 8, & 12; solid braided and double braided rope, mooring lines, specialty rope and twines available in polypropylene and polyester. We offer ropes in many materials such as nylon, polyethylene, and manila. Sunshine’s ropes serve many applications and industries including...

Whether you need rope for heavy pulling or everyday decoration, Hercules Bulk Ropes can help. Since 1975, Hercules Bulk Ropes supplies the highest quality rope at competitive prices. We want to be your number one source for all your rope needs. Our prices will entice you, but our customer-friendly service and expertise will keep you coming back again and again!

More High Strength Rope Suppliers

Types of High Strength Rope

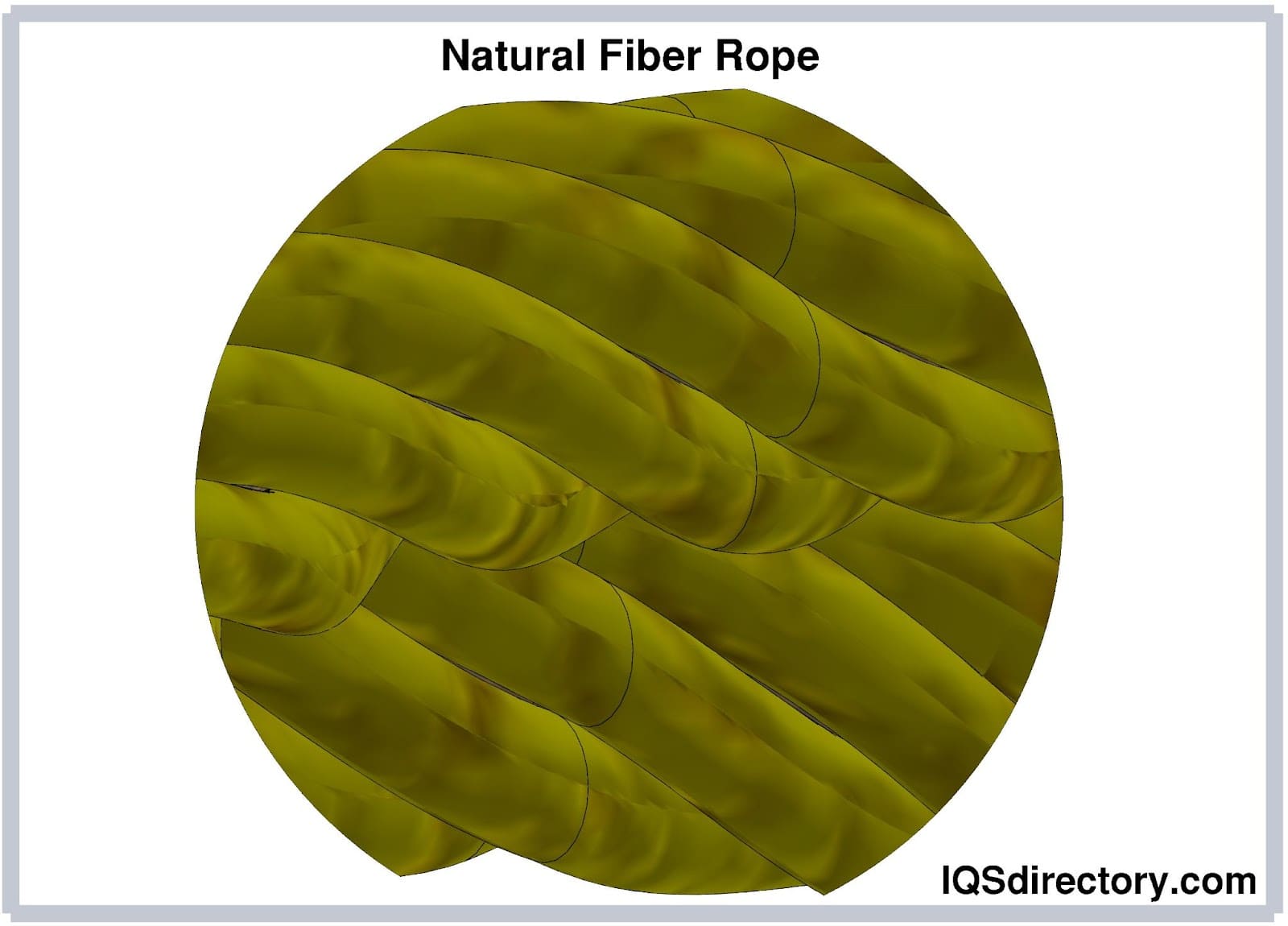

Natural Ropes

Natural ropes are made with an environmentally safe process using natural materials. Cotton, hemp, and sisal are examples of naturally occurring fibers. Natural and synthetic fibers mixed to create a stronger, more resilient rope. Although natural fiber rope is extremely durable in extreme heat exposure, it is vulnerable to moisture, mold, mildew, or ultraviolet light damage. Water exposure can shrink natural ropes, and they won’t regain their previous size and shape. Natural rope is useful for securing objects since it is non-slippery.

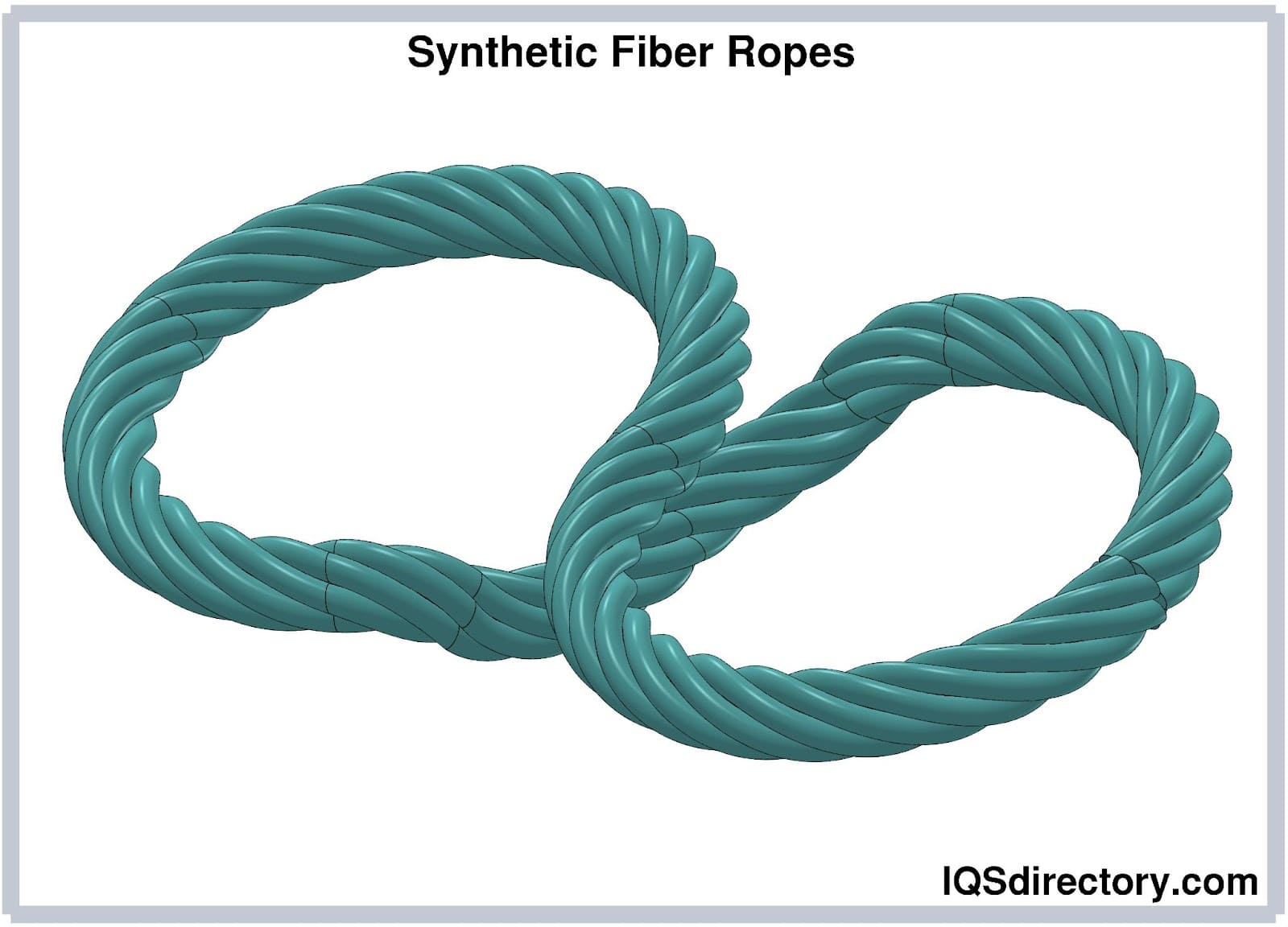

Synthetic Fiber Ropes

Synthetic fiber ropes are made of nylon, polyester, or polypropylene. They typically last around 30% longer than rope made of natural fibers. Wet conditions cannot harm these ropes. They are also not vulnerable to harm from UV rays, mold, or mildew, which makes them suitable in an open environment. Heat will cause synthetic ropes to melt, which will reduce their performance. They are not environmentally safe because of the damaging byproducts released into the atmosphere during the manufacturing process. However, synthetic ropes are a powerful tool for lifting or towing.

Construction of High Strength Ropes

Ropes vary by the style of twists or braids used in the rope's construction. These are divided into groups and named based on how they were built.

Single Braid Rope

Single braid rope is made of a solid braid. It is highly strong because the braids are interwoven, giving a robust appearance and strength. Therefore, it is a wise choice when an object needs to be pushed or raised under heavy strain or weight. Single braid ropes are typically used in pulleys or blocks. There are several sizes of single braid rope, ranging from 8 to 12 strands per rope and even eight plaited ropes.

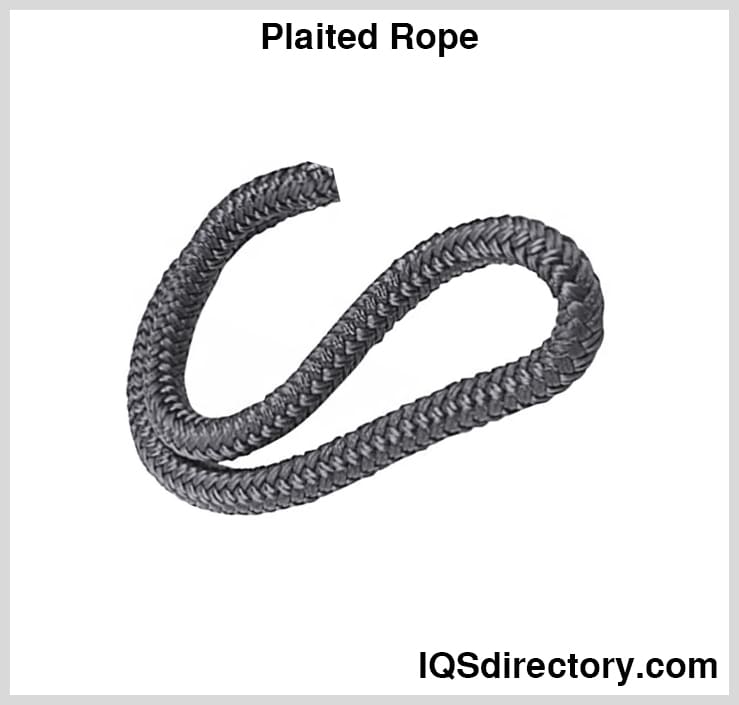

Plaited Rope

Plaited rope is thick to the touch and known as a square braid. There are four separate sets of strands in total. These strands are twisted and wound around one another to create a braid-like structure. These ropes are incredibly strong and flexible and can be easily tied. In plaited ropes, every strand is fully exposed to the environment because they are wrapped around a center. Therefore it’s easier for plaited rope strands to be damaged.

Twisted Rope

A twisted rope (also known as a lay rope) has strands coiled in the same direction. These ropes are less flexible and more likely to kink if handled improperly. Twisted ropes are used in dock lines and for towing.

Double Braided Rope

A double-braided rope is the best option for strength and resistance. Double-braided strands are wound around a double-braided core. These ropes are stable and flexible. They’re ideal for marine situations because of their abrasion resistance. Ropes with two braids are exceptionally durable and won't kink easily.

Hollow Ropes

Hollow ropes are empty or hollow inside. They are lightweight, weather-resistant synthetic ropes often used for suitable for anchor lines and ski tows.

Diamond-Braid Rope

Diamond braid ropes are formed by meticulously braiding fiber strands tightly around an inner core. These ropes have a robust, rigid structure. Their tightly woven construction gives them a nice appearance, so diamond-braid ropes are more expensive. However, they are reliably strong in demanding situations. In addition, ropes with diamond braids are simple to splice.

Choosing the Right High-Strength Rope Supplier

To make sure you have the most positive outcome when purchasing high-strength ropes from a high-strength rope supplier, it is important to compare at least 4 suppliers using our high-strength rope directory. Each high-strength rope supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each high-strength rope company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple high-strength rope companies with the same message.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services